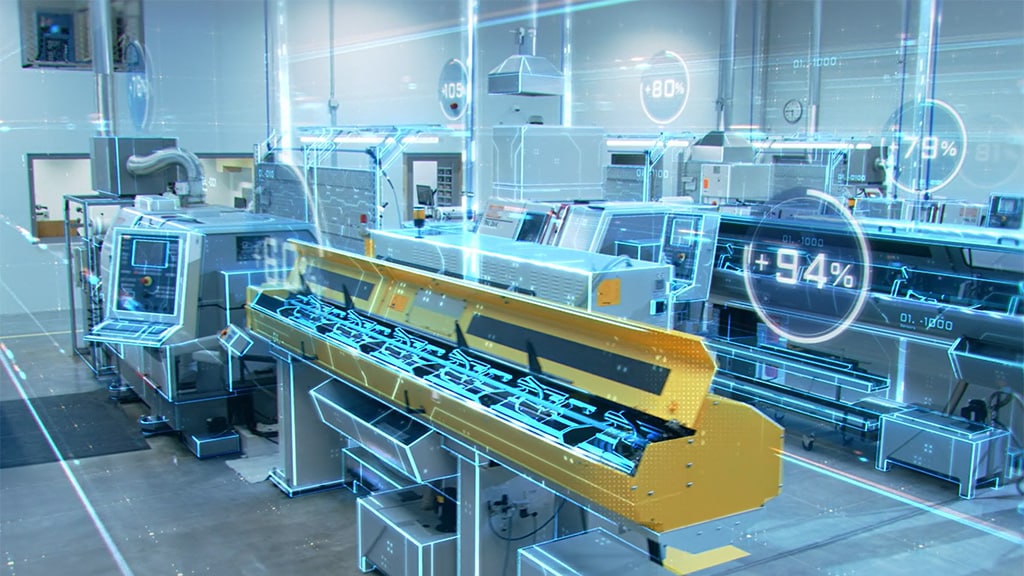

Edge AI enables optimization of manufacturing processes to reduce cost and optimize yield.

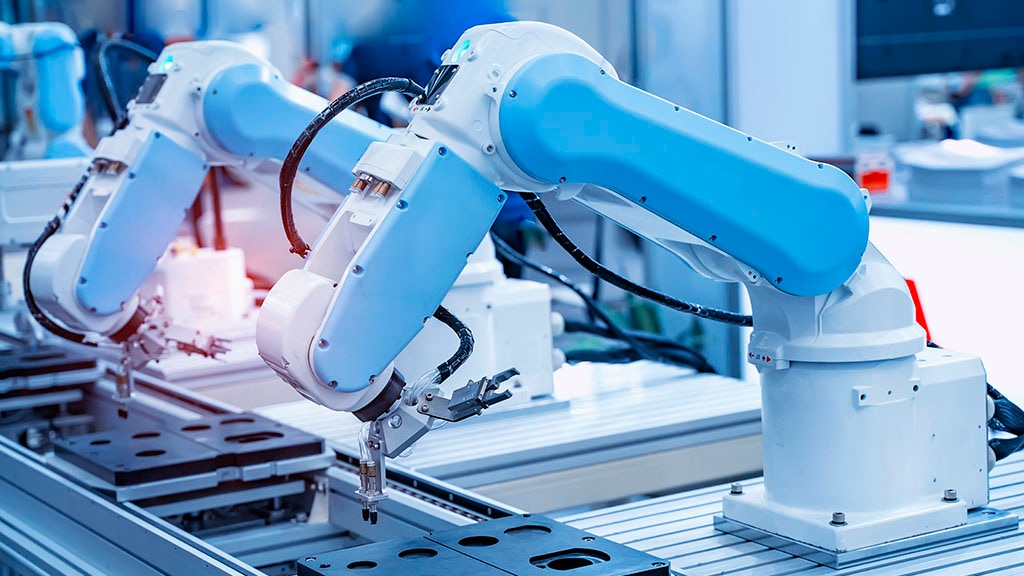

Computer Vision

Automation

Automation Smart Factory

Smart FactoryDefect Detection

Combine predictive AI and generative AI for automated operations

Real Time Monitoring

Product Inspection

Efficient Equipment

Machine Uptime

AI in Manufacturing

Streamlining end-to-end manufacturing challenges

- Workforce Health and Safety

- Automated Quality Inspection

- Mitigation of Skilled Employee Attrition

The manufacturing industry is leveraging predictive AI to address one of its most important and expensive challenges: workplace safety. Companies are using Edge AI hardware to connect data feeds from CCTV, machinery, and operational software to provide real-time predictive analysis of potential hazards.

Another significant application is automated quality inspection. For example, by continuously monitoring an automotive parts production line and feeding data into a predictive AI system, it is possible to provide real-time insights for quality control and significantly reduce the risk of defects.

Product Use Case

SYS-112B-FWT

AI-enabled automated quality inspection on the manufacturing floor is easily delivered using this system which supports a choice of Intel® Xeon® 6 series processors and GPU support.

AS -1115S-FWTRT

AI-enabled automated quality inspection on the manufacturing floor is easily delivered using this system which utilizes an AMD EPYC™ 8004 series processor and GPU support.

SYS-212B-FN4TP

Leverage computer vision and predictive AI to ensure workplace safety using this system which supports a choice of Intel® Xeon® 6 series processors and GPU support.